PVC Joining Process

What is the correct PVC Cementing Process, and Why should I use Primer?

Spears are the largest PVC manufacturer in the world, and their technical knowledge and experience is unparalleled. Waterworks have been installing and distributing PVC for almost 40 years now. Between us both, we’re sharing the key process in assembling a successful PVC connection.

So whether you're an experienced PVC installer, or greener than the grass on the other side, please go over this one more time.

Watch the process here:

WATCH VIDEO Spears® Solvent Cementing PVC of Small Diameter Pipe and Fittings

WATCH VIDEO Spears® Solvent Cementing Large Diameter PVC Pipe and Fittings

Or download the PDF on the installation process.

Misconceptions about primer:

Primer is referred to as cleaner, with the perception that it cleans the pipe. This is incorrect, the primer has a purpose of its own, and the material must be cleaned prior to application.

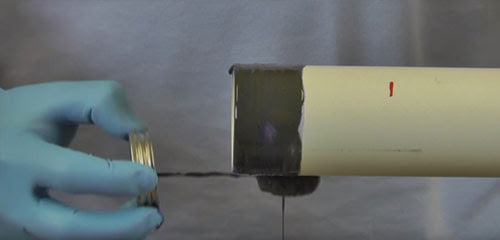

Primer is vital in the cementing process. It softens the materials so as to allow the pipe and fittings to fuse into one unit. After applying primer, a knife can be run along the surface of the pipe, and the material will easily peel off as shown in the video, proving the material has been softened.

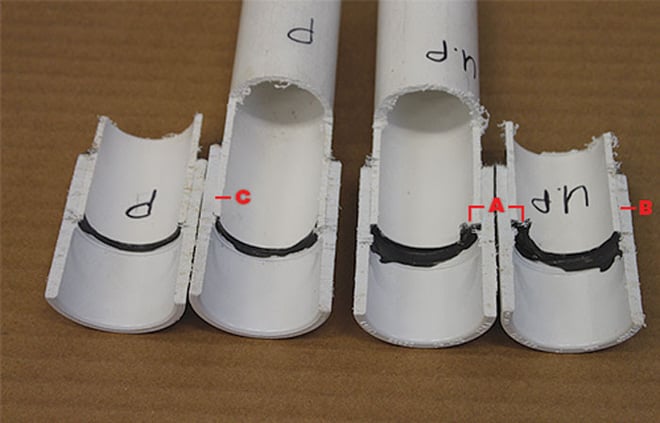

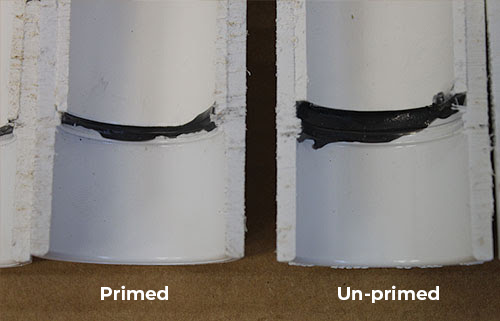

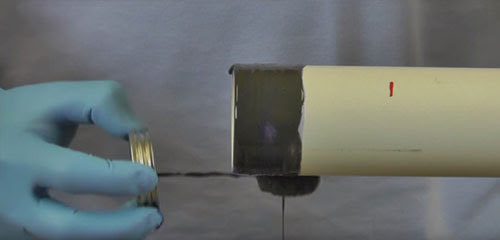

This photo shows a joint completed using cement only (items marked U.P for un-primed) versus a joint (marked P for primed) completed using primer and cement.

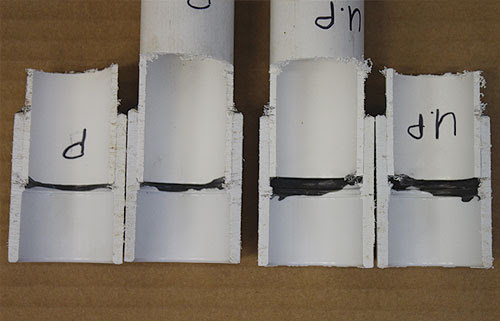

Comparing point B to point C in the photo, we can clearly see a difference, in that the primed joint (C) has fused together into one unit to the point that you can barely recognise a border between the two surfaces, whereas the un-primed joint line (B) is simply two surfaces stuck together – might as well use sticky tape.

We can also see that the un-primed pipe has not fully inserted into the fitting. Normally when you dry-fit prior to the cementing process to check the sizing of the pipe and fitting, the pipe should only go one third to two-thirds of the way in (refer to pdf instructions link). Using cement only, this doesn’t really change, as the material hasn’t been softened to allow the pipe to insert further. Instead, we can see in one spot (point A) that it has taken a skin off the PVC surfaces and pushed it out the end as we’ve tried to force it home.

This clearly demonstrates that primer does soften the material, allowing the pipe to be fully inserted, and ensuring the pipe and fitting are fused together into one leak-proof component.

-1.png?width=352&name=Copy%20of%20WW%20%20Blog%20headers%202023%20(19)-1.png)