What is PE pipe?

The use of PE pipe has significantly increased across New Zealand over the last 10 years, with quantities increasing sixfold. It’s a high-quality piping solution for your liquid and gas transfer requirements that can be used in both pressure and non-pressure applications. It’s highly popular across agricultural, civil, commercial, and industrial applications - and for good reason. This widely-used material brings with it various benefits, such as reduced installation costs, durability, and proven performance. To dig a little deeper into PE pipe, this article will explain its material composition, favourable properties, common applications, as well as the benefits of using it for your next piping project.

PE pipe explained

PE is an abbreviation for polyethylene which is a thermoplastic material created from the polymerization of ethylene. The process for making PE pipe is called extrusion which makes it easy to produce pipes of varying sizes. This pipe holds well under pressure which is why it’s utilised for a variety of pressure applications (more on this later). Typically, PE pipes can be purchased in straight lengths or coils which make long-distance installations easier. The pipes with smaller diameters are sold in coils while the pipes with larger diameters are usually sold in straight lengths. Being made of plastic, PE pipes are incredibly lightweight, which is advantageous for all scales of piping projects.

In addition, PE pipe is very flexible. As a result of this flexibility, PE pipes can conveniently accommodate uneven terrain, ground movement, and other obstacles. When flexibility and lightweight are combined, a piping solution that is easy to transport and handle is created; especially when comparing this to more traditional materials such as steel and concrete. It also has a high UV resistance which makes it an ideal solution for applications in direct sunlight. PE pipe is generally manufactured as one long connected piece of pipe that is cut to varying lengths. This makes it suitable for a wide range of applications, as explained below.

Particularly in the agricultural market, you may hear users refer to Alkathene pipe. Alkathene is in fact a brand of PE, not a type of pipe. Similarly, when users speak of Red Line or Green Line PE pipe these are also brand names given to different pressure ratings. There are three main types of PE pipe; Low-Density PE (referred to as LDPE), Medium Density PE (MDPE), and High-Density PE (HDPE). Typically LDPE is used in low-pressure applications, while MDPE and HDPE are used in higher pressure applications. You may also hear the terms PE80 or PE100 spoken of in the marketplace. In short, PE80 is MDPE and PE100 is HDPE.

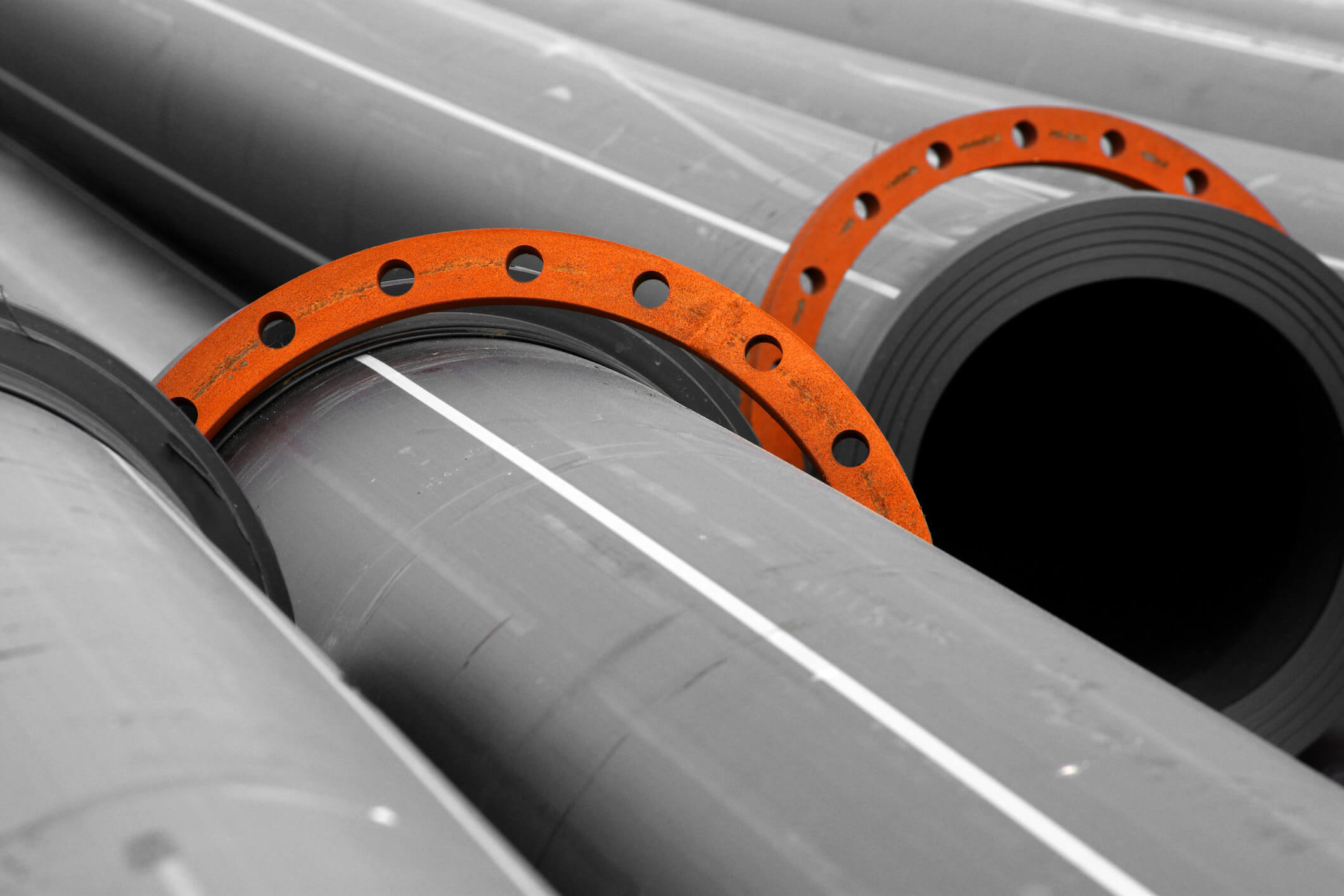

PE pipe

Let’s briefly speak about the sizing of PE pipes as this can also be confusing. Typically when we speak of LDPE, the sizing is related to a nominal bore or internal diameter size. For example, 50mm LDPE is referring to a 50mm nominal bore size. On the other hand, when we speak of MDPE or HDPE the sizing is based on the outside diameter of the pipe. For example, 50mm MDPE or HDPE will be 50mm outside diameter. When looking at MDPE or HDPE pipe you will also notice another marking that begins with SDR. This stands for ‘Standard Dimensional Ratio’ and relates to the wall thickness of the pipe. Common SDR ratings we see in New Zealand include SDR11, SDR13.6, SDR17, and SDR21. The SDR rating can be used to quickly calculate the wall thickness of the pipe which will subsequently allow you to easily calculate the internal diameter. To do this you simply divide the outside diameter by the SDR and this will tell you the wall thickness. For example, 50mm MDPE or HDPE with an SDR11 will have a wall thickness of 4.5mm.

PE pipe pressure ratings

MDPE and HDPE pipes will also have a pressure rating which usually begins with PN. The PN rating is the pressure rating in ‘Bar’. For example, PN16 is a 16Bar pressure rating. As with other plastic piping systems, the higher the pressure rating the thicker the wall of the pipe will be. This is where the SDR and PN ratings cross over. The higher the SDR rating, the thinner the wall and lower the pressure rating or vice versa, the lower the SDR the thicker the wall and the higher the pressure rating. There is a correspondence between the SDR and PN ratings. For example, SDR11 will be PN16 pipe, or SDR17 will be PN10 pipe.

PE pipe fittings

Now, what fittings do you use or how can you join the different types of PE? Typically LDPE will use a barbed type fitting which will insert inside the pipe and be held in place by a clip and cap nut which tighten up on the outside of the pipe to hold the fitting in place. As mentioned, this is typically for low-pressure applications. MDPE or HDPE pipes are typically joined using either a mechanical compression fitting, sometimes referred to as ‘Metric OD Compression Fittings’ like the Elysee range stocked by Waterworks, electrofusion fittings, or the butt fusion jointing method. Each fitting and jointing method has its own benefits which need to be taken into consideration for each application.

Common applications for PE pipe

With its lightweight and flexible nature, PE pipe has numerous uses. It can be employed as a solution across water transfer, irrigation lines (both effluent and water), high-pressure water mains, dairy shed pipework, gas, compressed air, and drainage pipeline projects. One of its most common uses is for water systems. This is because PE pipe has certain properties that ensure no toxins can leach from the pipe into the drinking water. PE pipes ensure the water supply is kept contaminant-free while being transported.

It is also commonly used to transport natural gas. Since natural gas can’t be stored in the same way other gases can, it must be transported through a reliable system. PE pipe is ideal for this application because of its durable nature and ability to safely carry natural gas underground. PE pipe is incredibly rigid which means it’s highly unlikely for the pipes to become compromised and leak fine substances such as gas or water. They can also be employed in low-temperature conditions without becoming brittle, making PE piping excellent for use in places that are often exposed to low temperatures.

Benefits of PE pipe

Reduced installation costs

One of the benefits of employing PE pipes for your next piping project is the reduced installation costs. Due to their flexibility, PE pipes can combat ground instability and enable the use of trenchless technology. This means that in busy settings such as roads, there is minimal disruption to traffic and businesses and the job can have a faster completion rate. This, in turn, can reduce overall installation costs.

Flexibility and strength

PE pipe’s flexibility is one of its most advantageous features. This makes it excellent for underground pipework which may be rocky, where movement may occur, or a high traffic flow is present. The strong but flexible character of this piping system is why it is used frequently in many agricultural, civil, and industrial applications.

Durability and proven performance

PE offers high abrasion and UV resistance and is compatible with a wide selection of chemicals. This is why it’s suitable for such a vast range of applications. It’s an incredibly rigid and proven material with studies revealing a life expectancy of over 100 years.

Recyclable

With the ongoing and increasing awareness for protecting the environment, one key benefit of PE pipes is that they’re fully recyclable. This enables manufacturers to reduce waste and implement recycling programs for unused PE pipe off-cuts.

Ultimately, PE pipe delivers a long-lasting and reliable piping solution. Ranging from applications across the agricultural, civil, industrial, and commercial sectors, PE pipe is well recognised for its ability to perform across New Zealand.

Waterworks have a wide availability of PE pipe:

- Up to 200mm 6-metre lengths.

- 25mm to 90mm is available in PN12.5 (12.5Bar pressure rating).

- 110mm to 200mm is available in PN10 (10Bar pressure rating) and PN16 (16Bar pressure rating).

With our extensive experience working with PE piping, we are well-positioned to ensure you’re using the optimal solution for your project and that it’s functioning efficiently and effectively. We provide a range of PE pipes that could be perfect for your next piping project. Get in touch with us today to enquire about PE piping or download our PE piping brackets technical information brochure by clicking on the button below.

-1.png?width=352&name=Copy%20of%20WW%20%20Blog%20headers%202023%20(19)-1.png)

.png?width=352&name=Waterworks%20%20PE%20vs%20PVC%20(1).png)