PVC pipes explained

As one of the most universal and versatile types of plastic piping to exist, PVC piping is employed in a multitude of different applications globally, specifically across the agricultural, industrial, commercial, and civil markets. In comparison to their metal piping counterparts, PVC pipes are lighter giving easier installation, offer greater chemical resistance, and in particular when compared to mild steel, offer greater corrosion resistance. However, they do have a risk of succumbing to thermal expansion or contraction. So while PVC will be the perfect solution for many applications, metal will suit others, and it’s important you know when one is more suited than the other. PVC pipes are offered in a variety of sizes with numerous fittings available and are safe for use in cold and warm water (operating temperatures of 4-40°C with temperature spikes up to 60°C) applications.

Focusing on agricultural, commercial, and industrial requirements for PVC piping, in particular, this blog will explain the material compositions, the sizing, common applications, and benefits of PVC pipes so you can be assured it’s the perfect material for your next piping project.

Material compositions of PVC pipes

PVC is Poly Vinyl Chloride which is one of the most commonly used thermoplastic polymers in the world. It has been around for much longer than most plastics and has proven itself as a reliable piping solution. There is also uPVC (Unplasticised Poly Vinyl Chloride). There is a misconception that the ‘u’ in uPVC indicates that the material is UV resistant, however, this is incorrect and both PVC and uPVC are not UV resistant. When standard PVC is exposed to UV radiation from sunlight the following conditions have been observed:

- A colour change, a slight increase in tensile strength, a slight increase in modulus or tensile elasticity, and a slight decrease in impact strength may occur.

- The effects of UV exposure do not continue when exposure to UV is terminated.

- The effects of UV exposure do not penetrate even thin shields such as paint coatings or wrappings.

It is recommended that PVC piping products exposed to the direct effects of sunlight be painted with a light-coloured acrylic or latex paint that is chemically compatible with the PVC products. Oil-based paints should not be used.

Moreover, offering such versatility in regards to it being durable, low-cost, lightweight, and easy to handle, PVC is commonly replacing more traditional piping materials such as metal, concrete, rubber, ceramics, and more.

Sizing of PVC pipes

Given the variety of applications for PVC piping, pressure ratings, and standards throughout the globe, the sizing of PVC piping can be confusing. For the purpose of this blog, we will speak specifically about PVC pipes in New Zealand. Typically the sizing of PVC pipe refers to the nominal bore (NB) size or nominal internal diameter. For example, when we speak of 50mm PVC pipe we are speaking about the nominal size of the bore or internal diameter. This does not mean the actual internal diameter will be exactly 50mm, this is a nominal number for ease of reference.

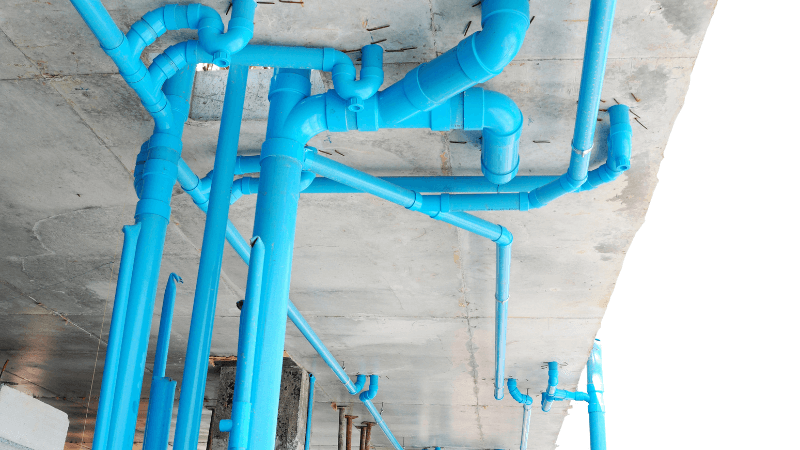

It’s also important to understand the type of PVC piping we are working with. Typically we use ‘Series 1’ PVC which is also known as PVC pressure pipe and is a white colour. We then have ‘Series 2’ PVC pipe, which is also a pressure pipe and is a light blue colour. This is generally used in civil applications and some large irrigation schemes. These are both manufactured to AS/NZS 1477. We then have DWV (Drain, Waste, and Vent) PVC pipe which is made to AS/NZS 1260 and often referred to as a drainage pipe. This is particularly in diameters 32mm to 150mm. Above these sizes, we generally use what is known as a Stormwater pipe which is manufactured to AS/NZS 1254. Both DWV and Stormwater PVC pipe are generally a light grey colour. When working in industrial, water treatment, or chemical handling applications, what is known as schedule 80 PVC piping is often used. This is dark grey and is American imperial sizing manufactured to the ASTM D 1785.

With all PVC pipe sizes, there are two constants; 1. The nominal bore size, and 2. The outside diameter of the pipe. What does vary is the actual inside diameter. With Series 1 PVC pipe (the most commonly used type) the internal diameter will vary depending on the pressure rating, typically known as the ‘PN’ rating. Similarly, DWV and Stormwater pipes are given a Stiffness Rating, also known as the ‘SN’ rating. Both the PN and SN ratings will determine the wall thickness of the pipe. The higher the PN or SN rating, the thicker the wall of the pipe and the smaller the internal diameter or bore size. For schedule 80 PVC pipe, there is only one thickness for each size pipe.

Common applications of PVC pipes

The most common uses for PVC pipes are water reticulation, irrigation, stormwater and waste disposal, swimming pool water, water treatment, and chemical handling. These pipes have an extremely long lifespan alongside being durable and lightweight which makes them a cost-effective and practical solution across their lifecycle. The smooth bore of PVC pipe helps to reduce the frictional loss on the pipeline compared to alternative materials.

There are two main jointing methods for PVC pipes. These are solvent joint and rubber ring joint. The solvent joint (often referred to as glue joint) method is where each length of pipe has one bell-shaped end and one plain end. The pipes are joined together by applying a primer which softens the plastic followed by a solvent cement which when joined together creates a fused connection. These are best for above or below ground applications and where a chemical is being conveyed through the pipeline. With the rubber ring joint method each length has one bell-shaped end with a rubber ring inside and one plain end. The pipes are joined by inserting the plain end into the rubber ring end and pushing them together. This makes installation, particularly for long runs easier, but is not recommended for above-ground applications or where a chemical is being conveyed through the pipework.

Benefits of PVC pipes

Cost-effectiveness and durability

With the first PVC piping systems installed being over 80 years ago and still in active use, and with the average life expectancy of a PVC pipe being over 100 years, it’s evident that PVC is an incredibly durable material. When designed and installed correctly, PVC’s natural ability to last a lifetime also equates to lower maintenance costs as there is no need to constantly replace it. Ultimately, opting for PVC piping not only ensures a rigid and long-lasting solution, but also a cost-effective one.

Safety

Lead-free PVC pipes are also one of the safest materials to use when it comes to drinking water due to its high corrosion resistance which makes it difficult for bacteria to breed. Alongside this, the PVC does not form any bio-film allowing it to act as a barrier to stop any contaminants from entering the drinking water. This also means that PVC piping is a key tool in safeguarding public health.

Environmental friendliness

There are many clear environmental advantages to employing PVC piping as opposed to other more traditional materials. For example, PVC is a low-carbon plastic that requires less energy and fewer resources to manufacture. Its lightweight nature also equates to less energy used in the transportation of the piping. The smooth surface of PVC pipes also reduces pumping costs and energy usage while the high-quality fittings prevent leaks and eliminate water loss. In addition to its long lifespan and low maintenance requirements, PVC pipes are also a recyclable material with many new pipes containing recyclates. This means that a certain layer of the pipe is composed of recycled PVC. They can be recycled multiple times without losing any of their technical properties. In fact, with every kilogram of PVC that’s recycled, approximately 2kg of CO2 is saved!

As PVC piping solution specialists, we can not only provide your business with quality PVC piping that will ensure your water piping system is functioning as effectively as possible but also the expertise to ensure you’re using the right solution for your project. Our range of PVC pipes and fittings fulfill demanding applications in the agricultural and industrial sectors of New Zealand. Its compliance with highly regarded quality standards paired with a proven track record makes our PVC piping a superior product. Ultimately, PVC piping delivers a high-performance, long-lasting, and reliable solution. Do you think PVC piping could be your ideal solution? Get in touch with us today to enquire about PVC piping for your next project, or download our PVC piping systems brochure for more information.

-1.png)

.png?width=768&name=Waterworks%20%20Brochure%20download%20banner%20(1).png)

.png?width=352&name=Waterworks%20%20PE%20vs%20PVC%20(1).png)