Is Europress suitable for compressed air piping?

Across an array of commercial and industrial applications, compressed air systems are an integral service. Compressed air systems can be very complex and intricate so it’s critical to have a full understanding of what piping system will provide you with the best long-term results, both financially and in terms of system operation efficiency and longevity. There are a range of considerations in a compressed air system, from upfront costs, operating and management costs, the efficiency of the system, to the added production value. For these reasons, it’s imperative that you make an informed decision and select the piping solution that will offer the best outcome.

That’s why this article will explain what Europress is, why it’s optimal for compressed air systems, the benefits of utilising the press-fitting system in compressed air applications, as well as key specifications for Europress in compressed air piping. The common question we get asked is “Why should I use stainless steel over aluminium or galvanised pipe?” and from installation speed to the quality of the operation system, there are numerous advantages to be gained in employing Europress in your next compressed air system.

What is Europress?

Europress stainless steel press-fit piping is a modern and transformational piping system. It’s leading the way in press-fit technology for New Zealand’s industrial, commercial, and agricultural sectors. Europress is designed and manufactured to the highest of standards in Europe. The manufacturer has over 40 years of industry experience which is evident in the precision of each fitting which has led Europress to be world-renowned as a superior piping system. It is an incredibly fast system to install with the utmost integrity at each joint while also providing significant savings to project installation costs, ongoing maintenance and service costs, and reducing shutdown times, which makes it an industry-leading piping system.

Why Europress is ideal for compressed air systems

The Europress stainless steel press-fit piping is ideal for compressed air system applications. One reason is its natural corrosion resistance, as well as its high strength and durability. This corrosion resistance is excellent for ensuring clean airflow, preserving and extending the life expectancy of your equipment, while the strength ensures the longevity of your system. Often the downfall of opting for traditional stainless steel piping systems is that it’s time-consuming to install, although technology developments in orbital welding are changing this somewhat. However, the Europress press-fit design eliminates this potential shortfall, making it the ideal piping solution for use in compressed air systems. There are a variety of additional benefits that come with choosing Europress, which we outline below.

Benefits of using Europress in compressed air systems

Faster installation speed and lower installation cost

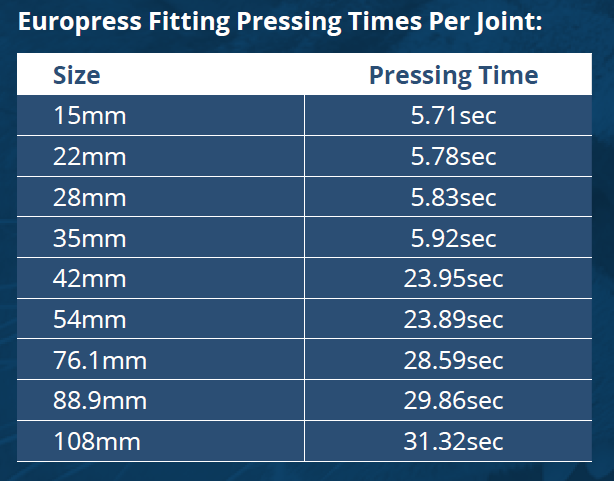

Europress is up to 10 times faster to install than conventional steel piping systems, which can result in savings of up to 30% on a project! Press-fittings are pressed in a single step using a battery-powered pressing machine which takes merely a few seconds. To be precise, below is a guide of the pressing time per join for Europress sizes 15mm to 108mm.

The savings offered by Europress are clearly demonstrated in a project at the Pernod Ricard Winery in Auckland where compressed air was one of the services Europress was used for. On this project, Europress was credited with achieving a 37% saving on installation. Furthermore, the installers were able to complete this project in 10 weeks compared to an estimated 24 weeks which meant the site was ready for the harvest season, saving Pernod Ricard from significant cost in lost production.

Better utilisation of labour

Tying in with its easy and speedy installation, Europress can be installed by any competent installer. This allows pipeline installation companies to better utilise their labour resources, bringing in younger installers while reserving their more experienced installers for more complex installs such as high pressure or process pipework.

Reliability

With Europress, the reputable German-manufactured tooling has preset torque settings which ensure every joint is pressed to perfection with a consistent amount of torque in one simple action. The battery-powered pressing machine is set to provide flawless and seamless installation every time and with its preset settings, reduces the chance of human error.

In addition, the innovative press check indicator sleeve and Leak Before Press (LBP) o-ring provide two additional quality control measures to ensure each joint is pressed and pressed correctly. For example, prior to installing Europress on his compressed air lines, Andrew Lawrie of Blue River Dairy had plastic pipe and fittings which leaked everywhere. After 6 years of having Europress press-fit piping, he has had not one leak which is a testament to the reliability of Europress.

The highest level of safety

Since each joint is pressed using the hand-held 18V crimp tool, there’s no need for gas bottles, hoses, or naked flames. This also means you may not need to gain a hot works permit for the installation and could eliminate fire watch requirements. Various risks come hand-in-hand with traditional welding including, fire risk, harmful gases and toxins, electrical leads, and heavy lifting of gas bottles and other machinery. When you use Europress, these risks are often expunged or largely reduced.

Why should I use stainless steel over aluminium or galvanised pipe?

This question is often asked in the context of stainless steel being perceived to be more expensive than aluminium or galvanised pipe. Whilst often this may be true when comparing like for like material costs, i.e. a six-metre length of stainless steel tube versus the same length and equivalent size of aluminium or galvanised pipe, some additional considerations from market feedback are as follows:

- Europress tube is available in both 316L and 304L grade stainless steel. Therefore, if you are installing in a non-corrosive environment, 304L is a lower-cost alternative to 316L and would provide a more direct comparison to aluminium piping at a material cost level. Some clients have said they have found Europress stainless steel to be cheaper than aluminium while others have said it is more on par.

- From a longevity perspective compared to aluminium, feedback has indicated that if the coating on the pipe is damaged, whether it be from a fitting or during the installation process, this can be a point where corrosion known as electrolysis stems from. This becomes increasingly problematic in an industrial or corrosive environment. Similarly, galvanised pipe is more susceptible to corrosion which poses the risk, particularly if it is internal corrosion, of flaking inside the pipework which transfers through the system and can cause clogging or damage at the outlet point which can be a major concern particularly if expensive processing equipment is involved.

- In comparison to galvanised pipe, from an installation point of view, Europress has a faster and less complex installation process compared to the thread and socket process. Feedback suggests this makes Europress competitive on the installed cost and less susceptible to leaks.

Key specifications for Europress in compressed air piping

- Pipe and fitting material: Tube - either 304L or 316L, Fittings - 316L

- Pressure rating: 16 Bar (232 PSI)

- O-ring Material: Viton

Waterworks is the New Zealand importer and distributor of Europress, providing a wide range of tube and fitting options. This means you have plenty of options when it comes to selecting the piping that’s right for your compressed air system. The press-fit construction of Europress is of the highest quality to ensure the durable, safe, and prolonged life of your piping system. In addition, the properties of Europress in compressed air systems ensure superior performance and efficiency of airflow, complying with the most stringent European and Australian certifications.

Discover more about the Europress piping range by simply clicking on the button below to download your free Europress brochure.

.png)