Carbon Steel for Heating Systems

Europress carbon steel press-fit piping system is becoming increasingly popular for closed circuit heating systems. Engineers, consultants, installers, and asset owners are reaping the benefits of using this high-quality product. The Europress offers significant advantages such as:

-

Lower cost.

-

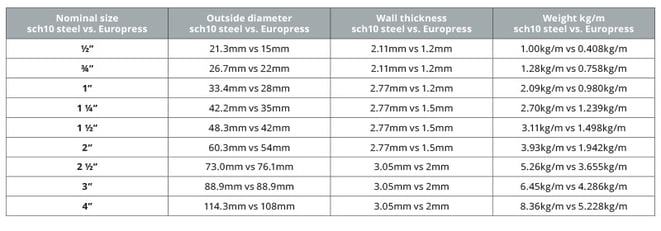

Easier handling for installers which has health and safety benefits.

-

Lowering the total material weight of the system on the building structure.

-

In some cases, greater capacity compared to pipes with the same external diameter.

-

Less environmental impact in both the production and moving phases.

Europress tube and fittings are treated with a galvanizing process to protect them from both internal and external corrosion. Europress has two options for the tube; one has galvanizing externally only, and the other has it both internally and externally. The systems must be closed circuit so no fresh air or fresh water can enter. We recommend using tube with external galvanizing only for closed circuit heating systems. The installation of these systems must be performed in accordance with the correct Europress process as prescribed. There are five key areas to focus on when using Europress carbon steel.

Transport and Storage

Water and moisture must not be allowed to infiltrate and/or form on the tube and fittings, and they must be kept free of dirt and condensation. Pipe must remain capped until such time as it is installed. Ideally the product should be stored in an atmosphere that has both temperature and humidity control. If this is not practical, product must be inspected periodically. There is a fine layer of protection on all tube to prevent corrosion during storage and transportation.

Installation

Avoid accidental impacts and pay particular attention to sharp surfaces which can cause damage, especially if they are of dissimilar ferrous metal materials which can facilitate the onset of corrosion. Carbon steel heating systems must also be protected from external corrosion agents such as salt spray and humidity. Extra precaution should be taken with buried pipes where external corrosion becomes particularly aggressive due to elements that may be contained in the soil and also resultant moisture. Some of the best insulation or protective measures are listed below:

-

Insulate with a synthetic closed cell insulation.

-

Paint with a protective paint.

-

Clad with a protective tape, ensuring 100% cover.

Never use a felt tape or sheathing as this retains moisture for an extended period, promoting corrosion.

Another important factor to consider is the expansion and contraction of the system. The pipe must be allowed sufficient space to expand and contract without restriction. The following formula should be used. If unsure, please consult the Waterworks technical support team.

The following formula is used to calculate longitudinal expansion:

∆L = α • L • ∆T / 1.000

where: ∆L is the expansion in mm;

α is the coefficient of expansion of the material expressed in mm/m • °C; For carbon steel the coefficient = 11.

L is the length of the pipe in m;

∆T is the permitted temperature difference

When filling the circuit, make sure no air enters. All air must be removed through a vent valve. New oxygen in the air and new water feeds internal corrosion.

Insulation

Pipework must be protected against freezing, as this can cause unnecessary stress leading to potential failure. A synthetic closed cell material is recommended. Closed cell insulation prohibits the transfer of air and moisture, whereas an open cell insulation allows this to be transferred and allows fluids to accumulate.

Condensation does not form due to heat. It is when the system cools that condensation occurs. Condensation, steam, and constant dripping onto the tube can facilitate external corrosion. Over time the galvanizing can no longer resist the corrosive action. Insulation removes this risk.

Insulation not only prevents the onset of corrosion but makes the system more energy efficient by minimising the dispersion of heat or cooling. When the temperature of the pipe is lower than the surrounding ambient temperature, the risk of condensation accumulating is higher, thus exacerbating the risk of corrosion.

Insulation must be sealed. Seal with a tape that is also made of closed cell material.

Pressure Testing

In order to prevent corrosion, the final testing phase is critical. Air and stagnant water must not be allowed to remain in the system too long before it is completely refilled. If the system is not going to be used immediately, it is best to do the pressure test using dry compressed air or an inert gas such as nitrogen. If testing is performed this way, slightly moisten the o’ring with water. Testing must be carried out at 1.5 times operating pressure and should be tested with both cold water and with water at the normal operating temperature.

System Maintenance

Carbon steel systems must maintain the closed-circuit condition without any air inside them. During the refilling and maintenance phases, a small amount of air could enter the circuit. This must be completely removed through a vent valve. Corrosion inhibitors must be used to neutralise any oxygen still present, therefore inhibiting any potential for corrosion. The system should be left filled even when not operating. If the system must be emptied and shut down for a certain period of time, it is recommended that dry air is passed through the system until it is completely dried, then the system is closed and sealed to ensure no fresh moisture or oxygen is allowed to enter.

If correctly installed and is well maintained, Europress carbon steel gives an economical system that will last for many decades.

References

http://www.eurotubieuropa.it/english/NL/2014/10/nl_10_1.html

http://www.eurotubieuropa.it/download/Eurotubi-Pressfitting_Technical-Guide_M-profile.pdf

https://www.neelconsteel.com/schedule-10-pipe-tables-technical-dimensions-thickness.html

.png?width=352&name=Waterworks%20%20Europress%20compressed%20air%20email%20graphic%20(1).png)

%20(1).png?width=352&name=Copy%20of%20WW%20%20Blog%20headers%202023%20(27)%20(1).png)

-1.png?width=352&name=Copy%20of%20WW%20%20Blog%20headers%202023%20(1)-1.png)