What Tapping Band is best for my piping system?

When it comes to piping systems, tapping bands play a crucial role in ensuring a reliable connection between two pipes and safeguarding against troublesome water leaks.

With many tapping bands available, however, it’s difficult to decide which one is best for your particular system.

In this article, we’ll discuss some factors to consider when selecting a tapping band for your piping system to help you make the best decision possible.

What Is A Tapping Band?

A tapping band, also known as a tapping saddle, is an efficient way to access a pipeline without having to cut out a section of the pipe to install a tee fitting. They are installed when a water connection or offtake is required.

Tapping bands are usually made of two cast or moulded pieces, that encircle the entire pipe’s circumference when bolted together securely.

There are two main types of tapping bands available:

- Mechanical Types, which are bolted to the pipe and have an elastomeric rubber seal

- Electrofusion Welded Types, which have a fully welded connection and are used with PE pipe

Typically, a female threaded or glued socket offtake is located midway on one half of the band, between the bolting points. Once the tapping band is bolted onto the pipe, a hole is drilled through the pipe's wall, matching the internal diameter of the tapping band's offtake port.

For the most common mechanical type tapping bands, an o-ring or lip-type seal is used within a seal groove surrounding the tapping offtake port and the hole, as it is drilled through the wall of the pipe to establish a seal between the pipe and the internal surface of the tapping band.

Applications

As previously mentioned, tapping bands are typically utilised when a water connection or offtake is required. They are smaller than the main pipeline that they are attached to.

Tapping bands are commonly used for water reticulation and irrigation hydrants, as well as for creating an entry point to a pipeline for installing measuring or monitoring equipment, such as pressure gauges, temperature gauges, and flow sensors.

These bands are used in above-ground or below-ground installations for the transfer of potable water, recycled water, and irrigation. They are also suitable for water services for the municipal, civil, agricultural, horticultural, industrial, and utilities industries.

Types Of Tapping Bands

While there are generally mechanical and electrofusion welded types of tapping bands, here are some of the specific options on the market.

Metric OD Tapping Saddle

Metric OD Tapping Saddles are commonly used to transport water, compressed air (low to medium pressure), certain chemicals, gaseous fuels, and slurries.

Metric OD Tapping Saddles are known for their UV stabilisation and chemical resistance. They are also often a much cheaper option. They feature stainless steel fasteners and a reinforcing ring to strengthen the offtake thread (on all the 4 and 6 bolt options).

The main disadvantage with these tapping saddles is as follows. Firstly there is a limited size range with a maximum diameter of 200mm. larger sizes also require more fasteners to secure. The band itself is wider than other types, which may limit its use in areas with space constraints.

These tapping saddles also have a lower pressure rating, particularly on larger sizes. For example, at 20°C, the pressure ratings are PN16 for up to 63mm, PN10 for 75 to 110mm, and PN6 for 125 to 200mm.

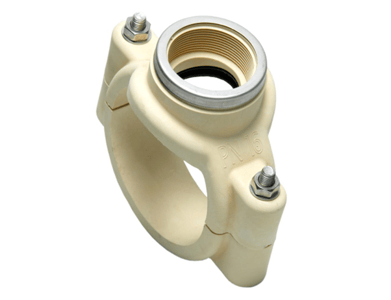

4N Composite Tapping Bands

The 4N Composite Tapping Bands are commonly used in high-quality water mains, such as municipal, civil, and council water reticulation systems, agricultural and horticultural irrigation systems, and frost protection schemes. They are a lightweight and sturdy alternative to traditional metal tapping bands.

What makes 4N Composite Tapping Bands stand out is their use of high-grade engineered glass-reinforced Noryl resin. This resin eliminates corrosion issues and provides excellent strength. It also has high heat resistance, good electrical insulation, low water absorption, excellent dimensional stability, good machinability, and low density.

4N Composite Tapping Bands are also incredibly robust, with a high-pressure rating of PN16 across the range and the ability to withstand temperatures from -40°C to 70°C. The pressure rating for these tapping bands is given at 20°C, and it needs to be derated as temperature increases because it is a composite material of construction. These tapping bands also come with 316-grade stainless steel fasteners of which the nut is coated with dry molybdenum to prevent thread galling, and they feature an E-Lip seal that requires low bolt torque to be effective and helps with both pressure and vacuum.

This tapping band has a special clamping design where the band holds itself onto the pipe during installation, making the installers job simple and easy. These tapping bands also have anti-rotation lugs moulded into the inner diameter of the band, preventing slippage on the pipe. It has been tested and approved for Watermark, WSAA, and to AS/NZS 4129 and AS/NZS 4793.

4N Composite Tapping Bands come colour-coded for easy identification, plus they are incredibly lightweight, reducing freight and transport costs. However, they only come in sizes from 40mm to 315mm and can be higher cost.

Electrofusion Tapping Saddles

This method is used to connect to HDPE pipelines. The Electrofusion Tapping Saddle provides a reliable solution for water mains, gas reticulation, municipal or civil council pipe networks, irrigation systems, frost protection schemes, and the mining industry.

Electrofusion Tapping Saddles are made from high-strength PE100 material and have high-pressure ratings across the range (PN16 for water and 1000kPa for gas). They create a high-integrity connection with a precisely moulded energizing coil of wire that ensures the uniform fusion of the PE material at the point of contact between the saddle and the pipe.

Because this tapping saddle is a composite material, the pressure rating given at 20°C needs to be derated as the temperature increases. Electrofusion Tapping Saddles are also limited in size, ranging from 40mm to 250mm. They require skilled operators to perform a welded joint to a high standard to be installed as well.

Gunmetal Tapping Bands

Pipelayers typically use this product to connect to PVC pipes and other similarly sized pipes for municipal or civil council pipe networks and individual property water connections to the main pipeline. They are often used underground.

With their high strength and durability for long-term performance, Gunmetal Tapping Bands are a great choice all around. They can also be used with a wide range of pipe materials, including PVC, PE, GRP (Glass Reinforced Polyester), and AC. These tapping bands are made of recyclable and dezincification resistant, or saltwater-resistant, material, meaning they are resistant to saline and saltwater ground conditions.

Gunmetal Tapping Bands come with 316 Stainless Steel fasteners that have an anti-seize coating on the nuts to prevent galling. They are made of strong metallic materials, which make them physically narrower than other options. Specifically, they come in a size range of DN50 to DN400. They have a high-pressure rating across the range (i.e. PN16) and are tested and approved for Watermark, WSAA, AS/NZS 4129, and AS/NZS 4793.

While they are a fantastic option for most, Gunmetal Tapping Bands are not recommended for use on CI or DI pipes unless appropriate insulation material is installed. This is because there is potential for bi-metallic corrosion between dissimilar metals. They are also susceptible to corrosion in certain ground conditions, and the cost can dissuade buyers.

Industrial Schedule 80 PVC Tapping Bands

This product is commonly utilized in industrial Schedule 80 PVC pipework for water and wastewater treatment plants, as well as chemical applications. They are often utilized to connect dosing points into a pipeline, measure and monitor equipment ports, create air and vacuum release connections, and create system drainage points.

Industrial Schedule 80 PVC Tapping Bands are known for their strength and excellent chemical resistance, as well as their high-pressure rating. They also are versatile in that they offer the option for threaded or glued socket offtake connections.

However, the pressure rating for these tapping bands is given at 20°C and must be derated as temperature increases. This is due to the composite material of construction. They are also a much more expensive option.

How do I choose the right Tapping Band or Saddle for my piping system?

To determine which tapping band or saddle is best for you, consider the following questions:

- What is the intended application?

- What is the operating pressure of the system?

- Will the installation be buried or above ground?

- If buried, what are the ground conditions (e.g. soil type, likelihood of corrosive elements, potential for ground movement, temperature, etc.)?

- If above ground, what are the environmental conditions?

- What type of pipe will be attached (e.g. PVC, PE, Cast Iron, Ductile Iron, Asbestos Cement, ABS, etc.)?

- What type of fluid will be contained within the pipe (e.g. water, gas, chemical, etc.)?

- What is the temperature of the fluid?

Once you have your answers, look through the list of tapping bands above and you’re sure to find one that meets a majority of your criteria.

Still not sure? Try looking through our Tapping Saddles & Tapping Bands options on the Waterworks website!

.png)

.png?width=352&name=Waterworks%20%20PE%20vs%20PVC%20(1).png)