Stainless steel pipe considerations in health & aged care facilities

In today’s market, there are many and varied piping materials to choose from and every material has pros and cons. Waterworks has been distributing the Europress stainless steel press-fit piping, a European manufactured system, for over eight years now and with the increase in stainless steel being used in both health and aged care facilities throughout New Zealand, I wanted to outline some of the key benefits stainless steel pipework offers this sector for both hydraulic and mechanical services.

There is good reason for stainless steel to be considered for building services in health and aged care facilities which can be summarised in the following:

- Stainless steel has very good corrosion resistance. This quality holds in the full range of potable waters, including soft waters and is particularly valuable in large facilities.

- Stainless steel pipework is particularly strong yet ductile.

- Stainless steel pipework is unaffected by high water flow rates.

- Stainless steel systems have low maintenance costs and other life-cycle costing advantages.

- Stainless steel pipework does not demand water treatment chemicals, other than for bacteria control, in fact on its own is less susceptible to bacteria growth.

- Stainless steel is non-toxic.

- Stainless steel is manufactured from a high proportion of recycled material and is 100% recyclable.

- It is aesthetically pleasing.

Europress installed at Grey Base Hospital, Greymouth, New Zealand.

We will now take a deeper dive into these benefits and explore them in detail:

What is stainless steel?

An iron alloy can be called stainless steel if it has a chromium level of 11% or greater. Different stainless steels offer a wide range of corrosion resistance and mechanical properties. In saying this, the two most common grades of stainless steel used for water pipework are 304 and 316.

304 and 316 are strong, ductile and do not become brittle at low temperatures. Their high level of corrosion resistance comes from a thin, adherent surface oxide film which forms immediately in contact with air and is self-healing if scratched. There is enough oxygen in piped water supplies to facilitate this healing and protective process. They can withstand water velocities of approximately 30 m/s, so erosion and turbulence effects are not a problem. Because of their high corrosion resistance, health and aged care facilities can eliminate the danger of pipework corrosion contaminating potable water supplies.

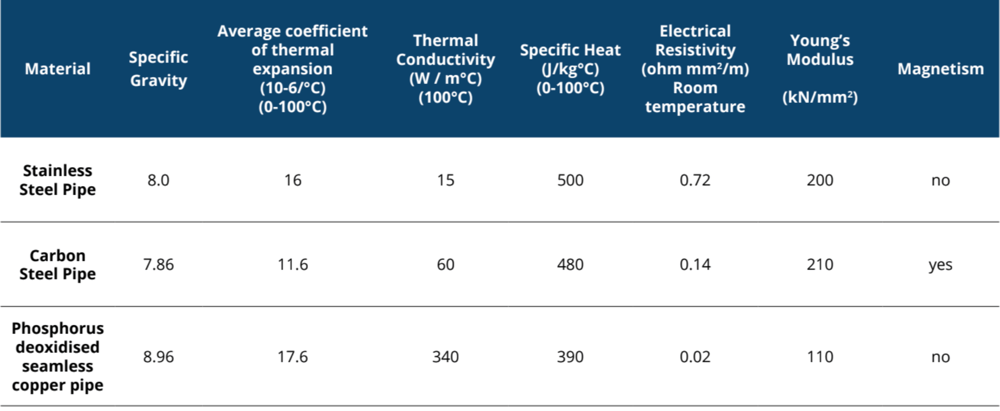

Key physical properties of stainless steel in comparison to Carbon Steel and Copper Pipe:

Key Observations

- Stainless steel is on average 9% less susceptible to thermal expansion than copper pipework while carbon steel is on average 27% less susceptible than stainless steel.

- Stainless steel has 95% less thermal conductivity than copper pipe and a much higher electrical resistivity.

Corrosion Resistance

Stainless steel is regarded as a premium product that is less susceptible to corrosion than other metallic materials. This resistance is due to the self-repairing passive oxide film which is formed. The resilience of this layer increases with chromium content and with the addition of molybdenum. The presence of nickel encourages the formation of a crystalline structure called austenite, which aids ductility and formability. The standard stainless steel alloys used in hydraulic and mechanical applications contain 12-30% chromium and 8-12% nickel. 316L which has been approved to the Australian Watermark standard must be used for hydraulic applications. 304L offers a lower-cost solution for non-potable applications such as mechanical services.

Waterworks strongly recommends choosing a supplier who can provide you with full traceability of the composition of the stainless, often done through heat trace numbers and material certificates. Refer to ‘Appendix A’ for material composition details.

A common cause for corrosion in stainless steel is when dissimilar metals come in contact with the stainless steel surface. This causes chromium levels in localised spots to fall below 12% which causes a breach in the chromium oxide barrier and pitting corrosion can occur. To avoid this, we recommend installing a non-ferrous spacer, usually a brass barrel nipple, at least 150mm long, to separate the two dissimilar metals and avoid cross-contamination.

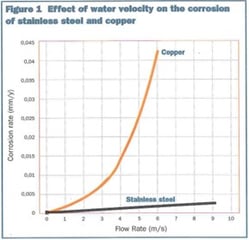

Stainless steel resists corrosion better than other metal pipes, even at very high flow rates. Figure 1 demonstrates the effect of water velocity on copper and stainless steel. We see that stainless steel performs well at velocities of more than 2.5m/s. It can resist corrosion due to turbulence downstream of orifices, elbows, valves, and pumps.

Localised breakdown of the protective film is very unlikely. Where chloride ions accumulate (tight crevices, stagnant water and under deposits), there is the potential for such breakdown. In practice, crevice corrosion and pitting of 304 grade is rare in natural waters containing up to 200ppm. 316 grade is equally rarely affected up to 1000ppm. To give this some perspective, the New Zealand Drinking Water Standards give a maximum allowable value for free available chlorine of 5ppm. The aesthetic guideline value for chlorine in consumers’ water is 0.6ppm. (Source: Wellington Water website. Refer to Appendix B). For high chloride waters and uncertain conditions, 316 grade should be used.

What’s known as stress cracking corrosion (SCC) has been seen at temperatures above 50°C when chlorides are allowed to concentrate on the surfaces. Research suggests it is very unlikely to occur in potable water systems with chloride levels less than 250ppm at the temperatures experienced in domestic systems. To preserve the ‘outside’ of the pipework chloride contamination should be minimised. For this reason, Waterworks suggests using chloride-free insulation.

Therefore, with high quality, properly manufactured stainless steel products we expect stainless steel to have a longer life-span, reducing maintenance or replacement costs over its expected life.

Design considerations to minimise corrosion risk

The following suggestions are intended to assist consultants and installers reduce the risk of corrosion in stainless steel pipework, particularly in systems containing chlorine:

- Horizontal runs should have a fall.

- Dead legs should be designed out.

- With high chlorine waters, 316 grade is better than 304.

- Chlorine-free insulation should be specified to avoid chlorides concentrating on outer tube surfaces.

- Low chloride sealants and anti-galling compounds should be used.

Performance Benefits

Water Flow Rate

The fluid flow rate in piping is usually affected by many factors such as pipe dimension and roughness. Comparing steel and copper piping head to head shows the roughness in copper pipes slows down the flow of water and other fluids.

Comparatively, stainless steel pipes allow for higher flow rates without running the risk of structural corrosion and pipe failure. This means stainless steel can handle a higher velocity than materials, such as copper or PP-R, meaning you may be able to reduce the size of the pipework required.

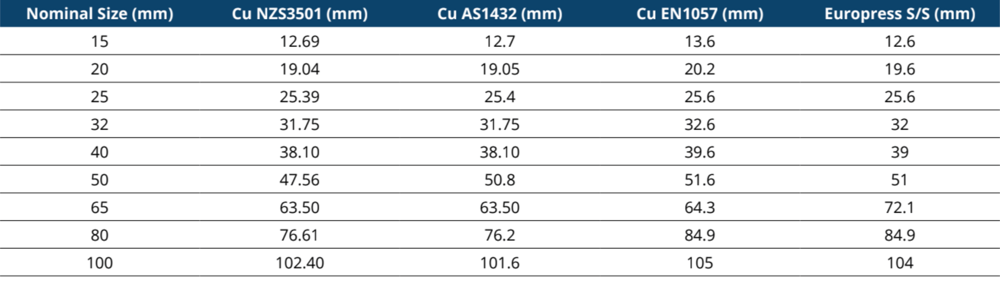

Stainless Steel Tube vs Copper Tube Internal Diameter Comparison:

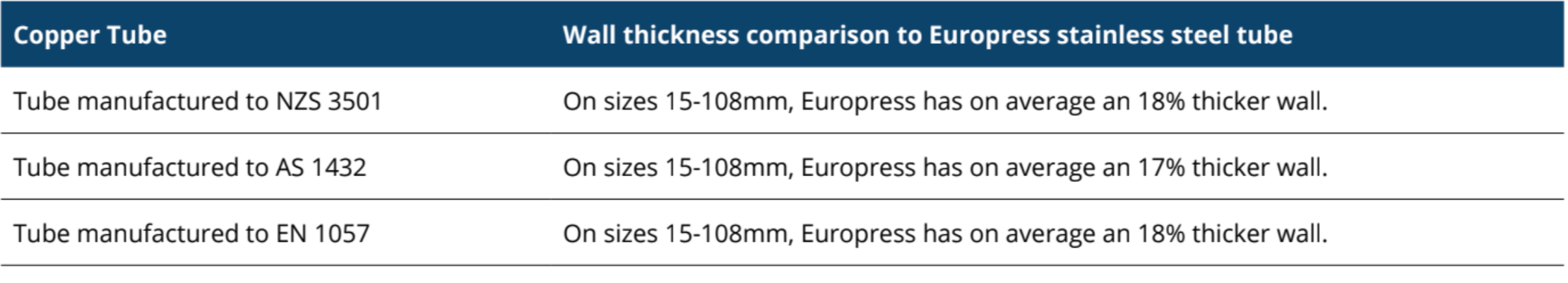

Tensile Strength

Stainless steel is on average 2.5 times stronger than copper and performs far better on the strain and stress tests. The relatively weaker structure of copper makes its piping vulnerable to external forces that may cause cracks and leaks. Below are direct comparisons between the wall thickness of copper tubes available in New Zealand and Europress stainless steel tubes:

This factor should be considered when making any piping material comparisons in relation to the pricing and longevity of the piping system.

Health Benefits

Copper Leaching

Humans can absorb reasonably large concentrations of copper without consequences, however too much copper can cause significant health problems. Copper can be found in various types of food, drinking water and even in the air. People, therefore, consume copper every day. The corrosion of copper pipes can lead to the introduction of copper ions into the drinking water system. This can lead to a flu-type condition called copper fever. According to WHO (World Health Organisation), the maximum copper content of drinking water must not exceed 2mg/litre. (Source: Stainless Steel World article. Refer to Appendix B). On the other hand, using stainless steel pipes this risk is eliminated.

Bacteria

There are various ways of treating water supplies to eliminate the spread of harmful bacteria. Bacteria tend to adhere to surfaces where they can form harmful biofilms. To do so, they require a ‘shelter’ in which to settle. Copper surfaces have been found to offer better ‘shelter’ than stainless steel, even though the opposite may be expected as copper is somewhat biocidal. However, stainless steel has a smooth, hard oxide layer which offers inferior accommodation to these micro-organisms. On the other hand, the topography of copper surfaces is more likely to promote bacterial growth than stainless steel. (Source: Stainless Steel World article. Refer to Appendix B). Hence the reason stainless steel is a preferred material where uncompromised hygiene standards are required, for example in hospital facilities.

Pipe Bracketing Considerations

One important consideration in a pipe installation is bracket requirements. Correct bracketing enhances the life expectancy of the pipework as it allows it to move appropriately to compensate thermal expansion while ensuring it is well supported removing unnecessary stress on the pipework and associated components such as valving.

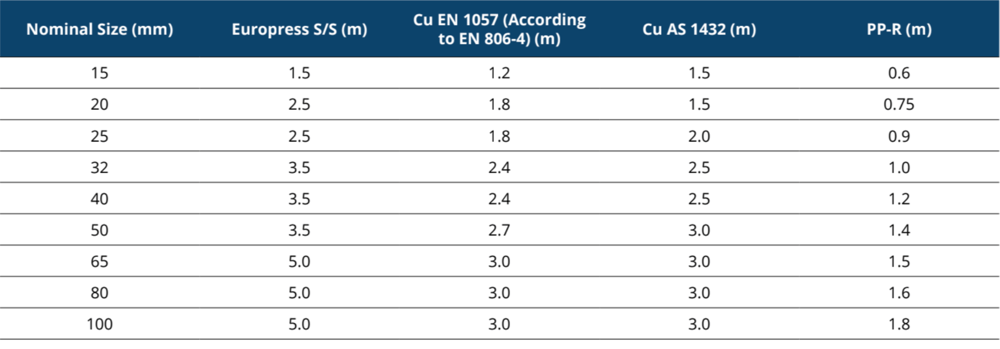

Along with correct bracketing comes a cost, not only for just the brackets but the required bracing to comply with seismic requirements. Below are some comparisons in bracket spacing between different piping materials:

This shows that with stainless steel, significantly less bracketing is required therefore reducing bracketing costs including the labour cost to install the bracketing.

Europress from an installation and ongoing maintenance perspective

When selecting a piping material for your project, two key aspects to consider are the installation and ongoing maintenance benefits. It is in these two factors that the Europress concept really comes into its own.

Installation

- Being a modular system, Europress is up to 10 times faster to install than conventional technology generating project savings of up to 30%. On a recent refurbishment at the University of Otago, an installer was able to complete the project in 2100 hours compared to the 3500 hours allowed for the project. In the food & beverage sector, Pernod Ricard winery was able to achieve a project saving of 37%. Read the full Pernod Ricard case study here.

- A simple and reliable installation process. When compared to other jointing methods, such as fusion welding, brazing, thread and socket, arc or tig welding, and even other mechanical joins, Europress is a very simple process to follow while the tooling having pre-set torque settings and safety features ensures each connection is consistent leaving no uncertainty of joint integrity. This significantly reduces the costly expense and delay of re-work.

- Europress improves health and safety with light-weight tooling, no gas bottles, electrical cords, no naked flames, or hot works. This reduces fire hazard risk and costly time spent completing permit paperwork.

- With a 25-year manufacturer back guarantee and full traceability of the Europress tube and fittings back to their European origin, you can have complete confidence and trust with Europress in your hospital or aged care facility.

Ongoing Maintenance

- In a hospital or aged care facility, minimising maintenance downtime and disruption is a key consideration for the long-term benefit of a facility. In a hospital situation, the feedback we have received suggests that in a shutdown scenario there is often a very limited window or four hours maximum. Given the speed at which Europress can be installed and the fact you don’t need to completely drain the system to make a join, installers can achieve more in the shutdown window or reduce the length of the window allowing the facility to get back up and running quicker.

- Europress stainless steel has more compatibility to a wide range of temperatures, water qualities, and duties meaning one system can service the lot.

- With no hot works, installers say they don’t have to worry about fire sensors, smoke alarms, and hot work permits.

Investment Value

Stainless steel has traditionally been viewed as a high priced product. However, in actual fact, the difference in price is not as large if at all as some may perceive. In fact, on a number of projects, stainless steel has worked out to be more cost-effective than copper.

If comparing Europress 304L grade tube and the standard 316L grade fittings, the most common combination for mechanical services, with press-fit copper, feedback suggests Europress is competitive in sizes 15-35mm and significantly more competitive in sizes 42-108mm.

If comparing Europress 316L grade tube and the standard 316L grade fittings, the most common combination for plumbing services, with press-fit copper, feedback suggests Europress is at a similar price point on sizes 15-54mm and then more competitive on sizes 76.1mm to 108mm.

If comparing Europress, either 304L or 316L, with PP-R, the stainless steel material cost is expected to be more expensive. However, when you consider the installed cost, for example, bracketing, which on a 50mm size PP-R requires 2.5 times as many brackets, and the installation time, this gap is significantly reduced and on larger sizes even reversed in favour of Europress.

It is important to note, although these comparisons are general in nature, they must be carefully considered in light of long-term benefits and the actual installed cost. When this is considered stainless steel becomes a very viable long-term investment for health and aged care facilities.

How can Waterworks help?

Waterworks can help you with:

- Specification writing.

- Installation protocols.

- Installer training.

- Onsite support including quality control assistance.

- Technical submissions.

- Provision of CAD & BIM files.

- An approved installer database.

If you would like to discuss your projects with our team please do not hesitate to reach out to us, we are here to help.

Appendix A:

Appendix B:

The following sources have been used in this blog:

- https://www.nickelinstitute.org/media/2422/stainlesssteelplumbing-color-en_11019_.pdf

- https://www.wellingtonwater.co.nz/your-water/drinking-water/how-is-it-treated/whats-in-your-water/chlorine/#:~:text=For%20supplies%20from%20unsecure%20water,system%2C%20to%20provide%20effective%20disinfection.

- http://www.eurotubieuropa.it/NL/StainlessSteelWorld2011_8.pdf

.png?width=660&name=Waterworks%20%20Contact%20us%20button%20(3).png)

%20(1).png?width=352&name=Copy%20of%20WW%20%20Blog%20headers%202023%20(27)%20(1).png)