The Importance of Getting Your Pipe Bracketing Right

Bracketing plays an important role in giving you the maximum or even extending the expected life of your pipework. There can be many and varied causes for pipe failure, but one common cause is poor selection and installation of bracketing. Issues such as using brackets of dissimilar metals or placing a bracket too close to a change in direction are common factors which can lead to failure. The following quick guide will give you an insight into correct bracket support, selection, placement, and anchoring.

Bracket Support Spacing

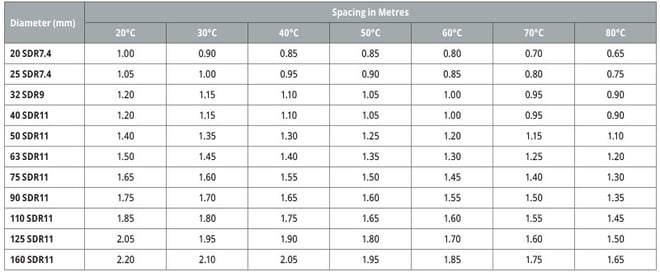

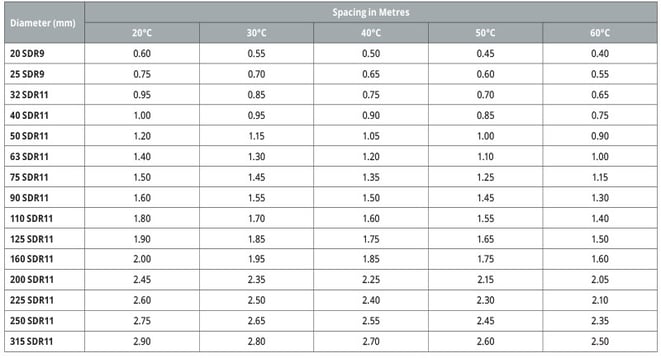

Support location and spacing depends on the following factors: pipework material, wall thickness, pipe diameter, temperature and weight of the product running through the pipework, and the location of any concentrated stress loads (i.e. valves, flanges, test equipment and any other heavy system components). Brackets must have an adequate load-bearing surface free of any rough or sharp edges that could damage the pipe during use. Bracket supports must not restrict linear movement of the system in order to allow thermal expansion and contraction from temperature fluctuations*.

*Refer to the below tables for bracket space for different pipe materials.

Bracket Selection

Many system parameters must be taken into account in the selection of the appropriate bracket. This can be affected by compatibility between the brackets and the pipework material, the immediate surrounding environmental conditions e.g. indoors/outdoors, coastal, etc. Brackets are available in a variety of materials such as plastics, steel, stainless steel, brass, but the material selected must provide adequate strength and support. Improper support can generate excessive sag resulting in premature pipe system failure. Brackets and supports used must permit axial movement of the system, but not compress the pipe. Supplemental, guides may be required in addition to brackets in order to maintain alignment and direct movement into in-line expansion joints.

Placement

Large amounts of stress can be placed on pipework, particularly at changes of direction, from thermal movement, water hammer, or vibration. It is therefore particularly important to ensure you support a change of direction properly. This doesn’t necessarily mean placing a bracket right at the change of direction, in fact this can be detrimental, but rather means a bracket is placed at a set distance back from the change of direction to allow the pipework to move and reduce stress. This will need to be considered for each different pipe material. This information is available in the Waterworks product technical guides. Heavy system components such as valves, flanged assemblies, tees, and other concentrated stress loads must be independently supported. Valves should additionally be adequately braced to prevent movement/stress loads from operational torque. Support of potential solids accumulation loads within the line should also be considered.

Anchor Guides

Anchors direct movement of the piping by providing restraint at key points. Such as long straight runs, at changes in direction of the system, and where expansion joints and other methods of thermal compensation are utilised. They may be used to control forces caused by expansion and contraction, pressure surges, vibration, and other transient conditions. Guides are necessary to help direct this movement between anchors by allowing longitudinal movement while restricting lateral movement. Depending on the application and type, guides may or may not act as supports. Support guides should have the same load bearing surface and other requirements of brackets designed for the system. Guides must be rigidly attached to the structure to prevent lateral movement but should not restrict longitudinal movement of the pipe through the guide. Anchors and guides must be engineered and installed without point loading the system.

Be sure to provide adequate pipework support to ensure the longevity of your pipe system.

Examples

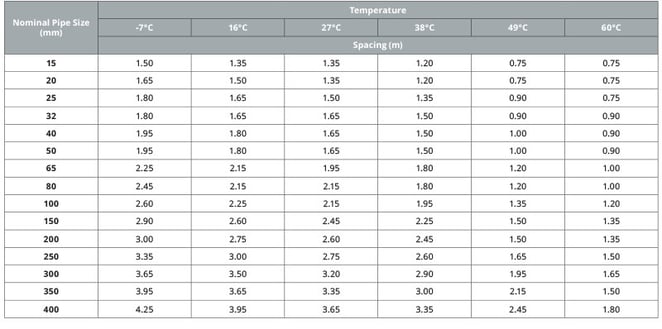

Recommended Pipe Support Spacing for Series 1 white PVC Pressure Pipe

The following bracket support spacing recommendations are according to size, schedule, and operating temperatures.

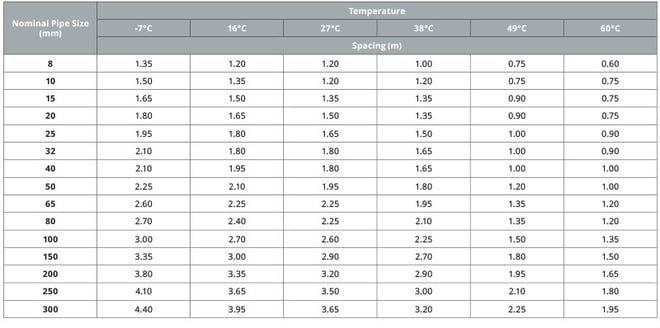

Recommended Pipe Support for Schedule 80 UPVC Pipe

The following Bracket support spacing recommendations are according to size, schedule, and operating temperatures. The below table is only intended as a guide.

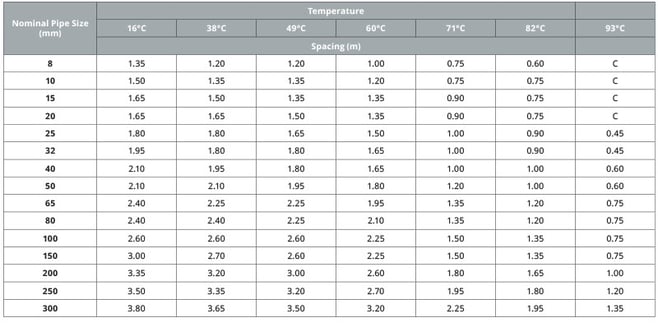

Recommended Pipe Support for Schedule 80 CPVC Pipe

The following bracket support spacing recommendations are according to size, schedule, and operating temperatures. The below table is only intended as a guide.

Bracket spacing for other piping systems and materials:

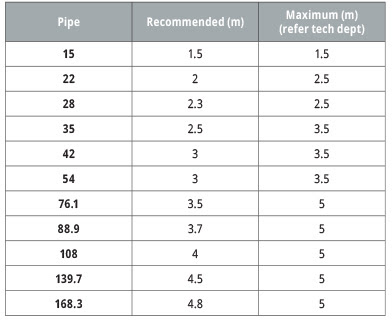

Recommended Pipe Support Spacing for Europress Stainless Steel and Carbon Steel Tube

Recommended Pipe Support Spacing for PN16 PP-RCT/Climatec Faser Pipe

Recommended Pipe Support Spacing for PN16 PP-RCT/Solid Wall Pipe

/The%20Importance%20of%20Getting%20Your%20Pipe%20Bracketing%20Right.jpg)

.gif?width=352&name=WW%20%20June%20blog%20cover%20image%20(1).gif)

-1.png?width=352&name=Copy%20of%20WW%20%20Blog%20headers%202023%20(17)-1.png)